Any company with international operations is familiar with the hurdles in everyday project work - time differences, lack of clarity in coordination and confusing project boards. They make international project work difficult.

Despite well-coordinated colleagues and digitalised communication processes, which are supposed to eliminate challenges, optimisation in everyday project work fails to materialise. That is why GE&PM relies on VESCON's project management software SO3 to significantly increase their communication and visualisation.

"The company is involved in plant construction and technical planning and was looking for a tool to successfully handle projects worldwide. Among other things, SO3 can offer exactly that," explains Alexander Isakov, SO3's technical contact.

Our client's manufacturing is primarily located in China. An advantage of this international set-up, besides great cost savings, is the time difference between China and Germany. Internationally active companies use this time difference to work on orders 24 hours a day.

One challenge with this way of working: Every task has to be coordinated. For project communication, GE&PM has relied on email or phone communication until now. Several thousand emails exchanged during different phases of projects showed the inefficiency of this method of communication. The result was an overcrowded inbox and no overview of current project phases and status messages. Consequently, the calls for a solution have become louder.

In addition to the desire for a solution to the international communication barrier and confusion about document versions, the new solution should preferably offer a cloud application and at the same time fulfil the requirement that the data fed into the projects be stored in a secure place. VESCON’s client also sought a tool that would function as a design database.

With SO3, VESCON offers software that is precisely customised to these requirements and fully covers the needs in international project management.

"One of the main reasons we went for SO3 was VESCON's area of activity in the industrial plant business. The software was developed to meet the demands specifically in this area," explains Ronny Teutsch, Senior Electric Engineer at GE&PM.

In addition to the possible area of application in process engineering, SO3 also supports customers in other versatile industries: automotive industry, process industry, pharmaceutical industry and in technical building equipment. An added value that was an important factor for the cooperation. The parallel use of a database in which everyone can enter their data in real time and work independently is fulfilled with SO3.

"With SO3 we work with software that is perfectly tailored to our needs. This is due to the individual database with its own master data and individual configurations. We can use it with great freedom and we can independently add things that we need," says Daniela Stirn, Head of Mechanical Engineer at GE&PM, describing the use of the software.

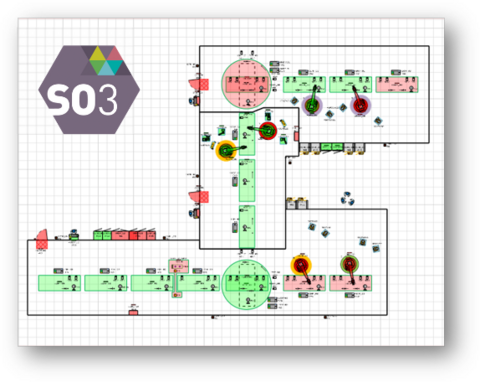

The VESCON software offers the advantage of working directly with intelligent graphics. Whereas in previous GE&PM projects work was done without the use of professional project management tools, SO3 makes it possible to link intelligent 2D and 3D plant layouts with synchronised lists. This provides a data layer from which important information can be directly derived. In this way, typical questions of the daily project business can be answered quickly in the simplest way, which would otherwise have to be worked out in a time-consuming manner. At the same time, all project participants can work in one database. Everyone can enter and manage data themselves. In doing this, everyone involved in the project is integrated in real time.

Now the company relies on the help of the VESCON software SO3 from the start of the project to the end of commissioning. Due to its flexibility, the tool is applied differently in the different project phases. At GE&PM, SO3 is used wherever electrical components are used and where teams work together, especially on an international basis. In process engineering, conveyor technology as well as in workplace equipment. Electrical equipment ordering is also handled with SO3.

"Fortunately, we have found a way to manage communication effectively and stay up to date with the latest project developments despite the distance in time and space," confirms Daniela Stirn from GE&PM.

Learn more about SO3.