VESCON updates now available on the brand-new Member of SCIO Blog

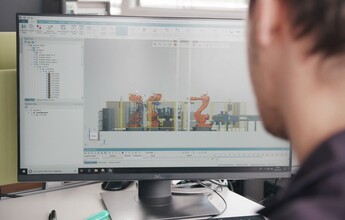

Explore news, case studies, in-depth reports, and much more from the world of VESCON and SCIO - because together, we're shaping the future of automation. 🚀✨

Since 2019, the VESCON brands have been continuing their success story as part of the SCIO Automation Group. Today, SCIO stands as one of the world's leading companies in automation across the entire value chain of the Smart Factory.

The SCIO Group brings together the collective expertise of now 12 corporate brands, each with decades of success in their respective industries. Through this close collaboration, as VESCON Automation, Energy, Process and Aqua, we've not only forged strong partnerships but also ensured our customers benefit from our comprehensive range of services, powered by a strong corporate group.

To immerse you even further into the world of VESCON as part of SCIO, you can now discover the latest news and compelling stories about VESCON and its partner companies on our shared news portal! We invite you on a fascinating journey through the world of intelligent industry of tomorrow - from automated intralogistics and production solutions to accompanying services and beyond.

All news articles are available for you right here: https://www.scio-automation.com/update

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/2/3/csm_APG_02a_Luftbild_optimiert_4968d100cd.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/d/6/csm_automatica_27.-30._Juni_Muenchen__4__be2c3b2fd5.png)