PMC

Success at the push of a button.

The automation of process engineering systems has become an ever-increasing challenge. The growing size of the plants and the increasing complexity of the processes continuously call for new solutions - true to the motto "Today's future is tomorrow's standard". The key to success is the close cooperation between plant engineer and automation specialist. We contribute our part to this common effort on the basis of our profound know-how, long years of experience and the ongoing training of our staff.

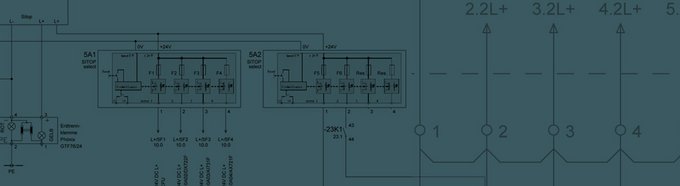

The equipment, too, plays a key role: In order to provide flexible, efficient and cost-effective solutions to automating issues we use intelligent CAE planning tools. It goes without saying that the programming and handling of process control systems, visualisation systems and programmable logic control units of leading manufacturers are natural parts of our services.

Among our clients are global players as well as medium-sized companies. Our customers operate in branches of industry that demand a high quality and reliability of products and systems: medical devices, bio-technological and pharmaceutical industry, chemical/petrochemical industry, oil and gas, energy, food & beverage as well as automotive industry.

PMC

D-67227 Frankenthal

Unit lead EMSR/PLT Frankenthal

Phone +49 6233 6000-554

giuseppe.cascarano@vescon.com